Euro-me departures to Germany for ROLAND training

Source : Euro-me Shenzhen Trade & Development Co., Ltd. Time : 2017-02-15 Hits : 6439

In June 2016, our ROLAND team departures to Germany for 5-day training in Roland and its subordinated products and technology exchange.

We have conducted a deep training in Roland factory. Except for E20、UDK20、I20 and other double sheet detection, we learned L20 which is based on 3-channel solution,the new Spring loaded sensor bracket SHX-42-DL and the new data backup RPP 1000. Roland develops a new remote maintenance solution RSB, which can provide a quick help during setup of new tube batches and new types of tubes.

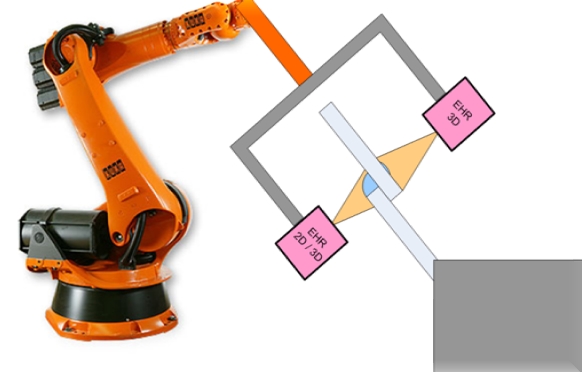

Additionally, our team is trained for the subordinated brands EHR and KURSCHAT. As the general agency, we will spare no efforts in promoting our outstanding products and solution.

EHR is a non-destructive control and inspection of Weld Seam. The function of the Weld Seam Control System EHR® AluCheck is based on the principle of laser triangulation and optical matrix measurement. It allows the inspection of the surface and of the geometry. The EHR® AluCheck System has been proved suitable for aerospace and automotive. Over 150 sets automatic system has been installed for the inspection of weld seam.

Mercedes-benz C Class manufacturers are using EHR inspection of weld seam.