| Brand : | EXAIR |

| Manager : | Tom Gong |

| Phone : | 0755 - 8384 2040 |

| Fax : | 0755 - 8384 2050 |

| Email : | exair@euro-me.com |

| Website : | www.exair.com |

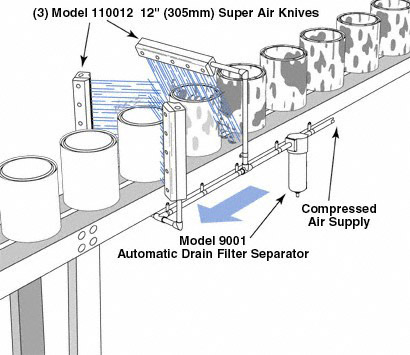

CASE STUDY: Engine Block Sleeve Blowoff

The Problem: A manufacturer of large engines installs machined cylinder sleeves in the block to resist wear. After machining, the sleeves are put through a parts washer for cleaning. Heavy amounts of honing oil remained on the sleeves. Numerous wash cycles and frequent changes of the contaminated washing solution were required.

The Solution: (3) Model 110012 12" (305mm) Super Air Knives were installed to remove the oil. A Super Air Knife above the conveyor blows off the oil from the grooved ring on top of the sleeves. Seconds later, another set of vertically mounted Super Air Knives wipe the remaining oil from the sides.

Comment: Production rates dramatically increased by cleaning the parts the first time through the washer. The compact Super Air Knife is the ideal solution since it generates a high volume, high velocity sheet of airflow. It provides a balanced airsteam that hits the entire surface with uniform force. This same arrangement of the Super Air Knives is also perfect for drying and cleaning other cylindrical shapes such as aerosol cans, buckets, jars, paint cans, bottles, etc.