The LEADER presetter family; high precision instruments that can reduce, even substantially, production costs by cutting machine set up time.

User friendly software, anyone can check shape and dimensions of tools and inserts.

Interchangeable tool sleeves, changing tool sleeves requires only one quick move and a few seconds for perfect tool centering.Each tool sleeve has calibration spheres embedded for fast X and Z zero setting.

High definition camera shows tool profiles and surfaces with micrometric precision.

Designed down to the smallest detail, high quality components and over-engineered structure guarantees years of trouble free work and constant performance.

LEADER presetters can:

- Determine height and radius/diameter of any tool in a few seconds

- Adjust insert positioning, angles and radiuses of cutters and knives

- Verify complex tool geometry

- Verify radius,height and position of cutters in multiprofile tools

- See tool surface in Real View mode

- Printing labels and tool list database

- Screenshot captures in PDF format

Scheda Tecnica

PRESETTER STRUCTURE

- Ø 320 ÷ 520 | H 360 ÷ 600

- Tool weigh with needle bearing support between tool and tool sleeve – 70Kg

- The structural components are all heat treated

- Recirculating ball bearing linear guides with preloaded slides

- ISO/BT/HSK/VDI interchangeable rotatig spindle holder

- Optical scales

- Axes resolution: X = 0.001 mm. Z = 0.001 mm

- 17” TFT 17” colour monitor

- PC housed within the presetter

- Nr. 7 usb output

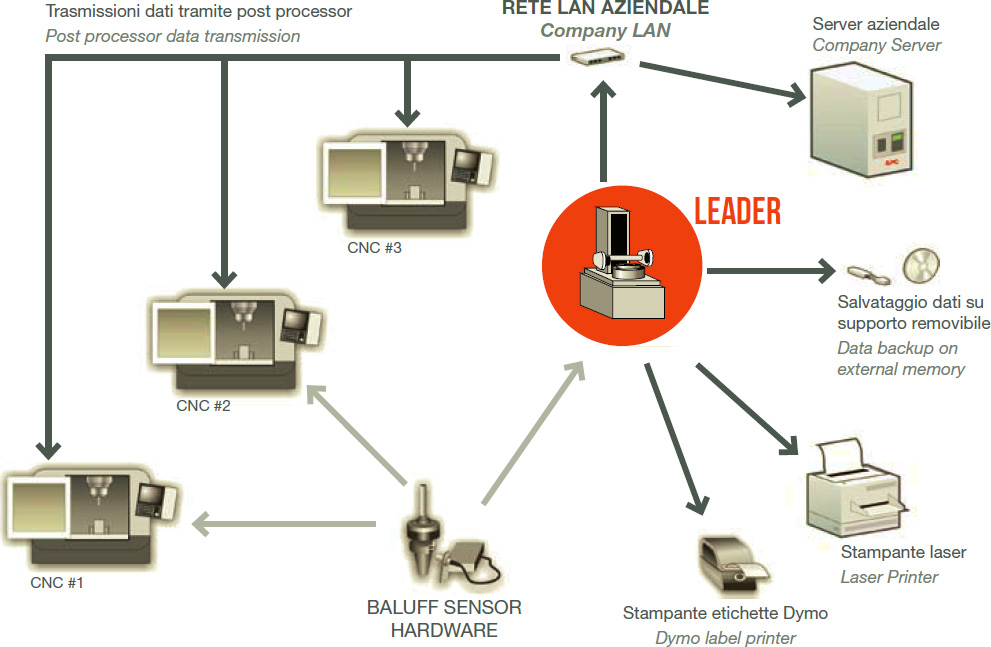

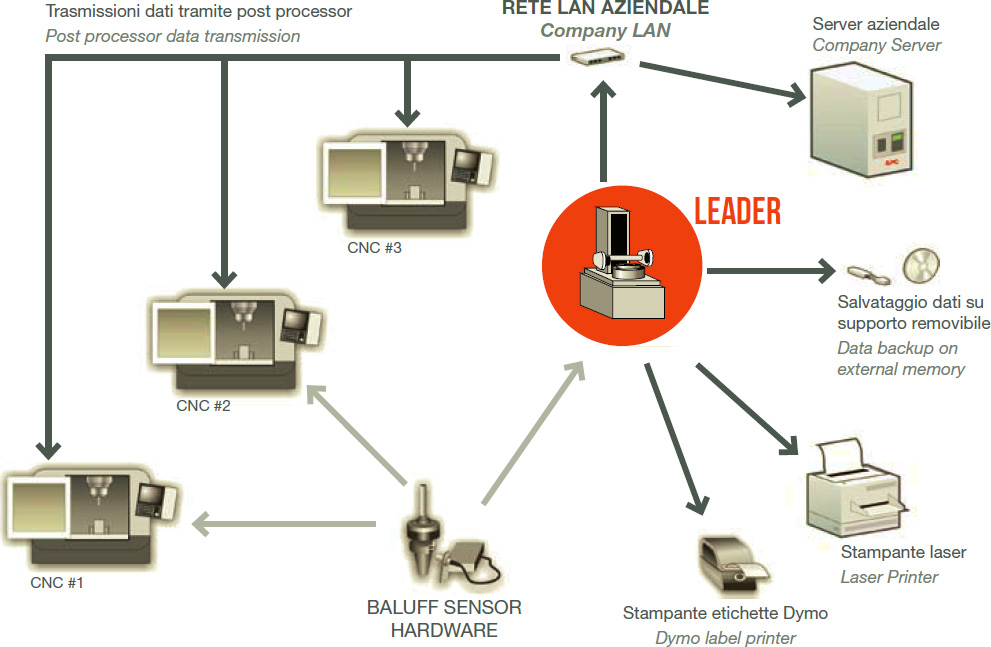

- Nr. 1 Ethernet - Lan output

- High resolution C-MOS camera

OPTICAL SYSTEM

- Telecentris Lenses

- Field of view 7x7 mm

- 40 X Zoom

STANDARD SOFTWARE

- Measurement system: fied and mobile axes with automatic measurement of maximun diameter and

- 20.000 tools storing

- 200 machine origins storing

- Shaped tools profile storing

- Tool list and label printing

- Complete geometric functions

- Language slection

- Software Update through Internet Connection

ACCESSORIES

- 17” touch screen Monitor

- Label printer

- Colour laser printer for A4 format

- Post processor

- Data sending presetting to Balluff system

- Presetter holding cart

- Pneumatic system, vacuum operating, for better cone locking

WEIGHT AND DIMENSIONS

- From 110Kg. to 150Kg. depending on model

- From 1100x620x900H to 1200x620x1040H depending on model